How to solve the problem of level detection in one stop

In summary:

This paper mainly introduces the application status and limitations of level meters in various industrial industries, and expounds the optimal solutions of the series products of Beijing Jinde Chuangye Control Technology Co., Ltd. in different industries and under different working conditions. The products include Limaco radar produced by Russian military technology, 3D level scanners, 26G radar products produced by joint venture, etc.

Introduction:

With the improvement of the level of industrial automation, the application of level meter in various industrial fields is more and more extensive, more and more important. The accuracy and stability of level meter directly affect the safety production, output and production efficiency of enterprises. Due to the inaccurate measurement of a level meter, there is no supply in the silo or liquid tank, resulting in mechanical burning, pipeline blockage, waste deposition on the operation platform, and ultimately affecting the production of the whole plant.

Although all factories purchased all kinds of materials and liquid level meters at the beginning of construction, they did not dare to use the data collected by level meters for chain control because of product quality, performance, working conditions and difficult maintenance of field instruments. Therefore, most factories only take the measurement of level meters as a reference data, or simply give up using level meters. For the height of materials in the silo, it is impossible to realize the automatic interlock control of material level meter by manual shift measurement, which greatly increases the labor intensity, labor risk and labor cost of the factory.

In fact, in the practical application of various complex level conditions, no single product of any brand can solve all the problems, and no product is omnipotent. Therefore, under various conditions, we must choose the best product and the best solution according to the actual industrial and mining conditions. It's not easy to achieve this, because most of the manufacturers and brands can't provide perfect level solutions due to the restriction of single product, single performance, no cross brand sales, on-site experience and model selection. But why can Beijing Jinde Chuangye Control Technology Co., Ltd. solve all kinds of level detection problems in one stop?

The reasons are as follows:

1. Beijing Jinde is a professional company specializing in the research and development, production and sales of level products. At the beginning of its establishment, the company positioned its development direction in the level product market. For more than ten years, it has been persisting in exploring, researching, developing and introducing new products and high-end technologies in the level field. Therefore, it has accumulated a large number of professional personnel in the field of material and liquid level, as well as experience in solving difficult problems in the field of material level detection.

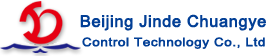

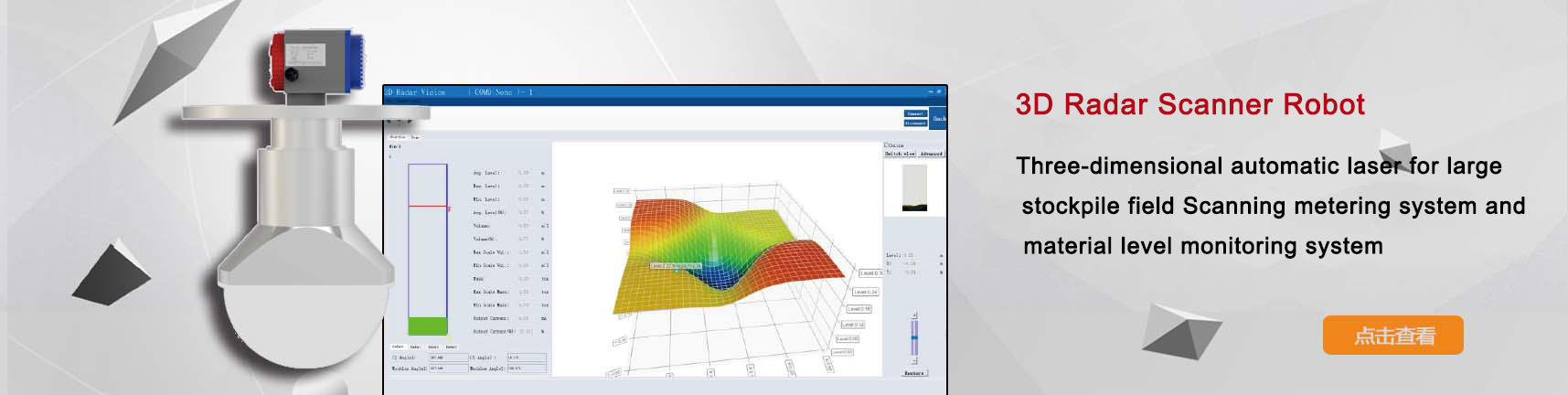

2. In 2010, the company introduced and acted as the sole agent for the 3D level scanner from Israel, thus solving the problem that the previous level instrument could not detect the whole material surface in a single point. The 3D level scanner can simultaneously display the highest, lowest and average level in the silo, and display the shape image of the material in the silo. At the same time, it can also measure the volume of the material. The historical curve data can be consulted through the 3D software. The technology can work normally under the condition of high dust, and has the function of self-cleaning for the dust adhering to the antenna. The only level detection technology in the world has created a new concept and a new chapter in technology of level monitoring.

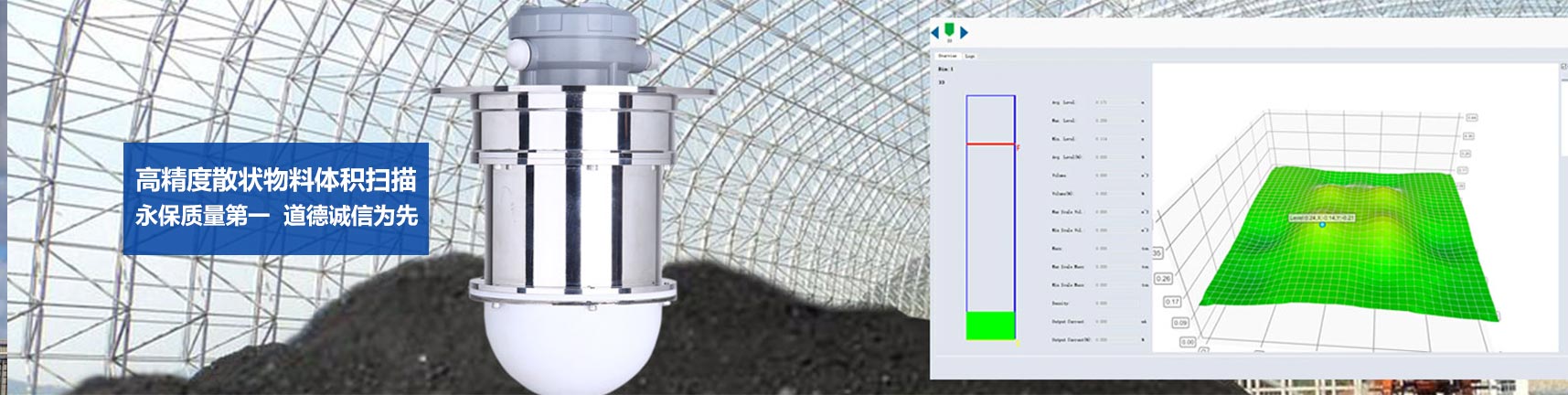

3. Beijing Jinde is well aware of the complexity of all kinds of material level detection, and knows that no product can solve all the material level problems. Therefore, in 2011, the company introduced and acted as the sole agent of the former Soviet Union's military products - Russia's LIMACO series radar products. This series of products use the highest frequency of 94GHz in the global industrial field, which can achieve the narrowest beam angle to 1.5 degrees, thus greatly reducing the interference of complex shapes in the silo. For its working principle, it adopts the working mode of FMCW which is difficult to break through in technology. The product series is characterized in that it can work well in very complex dust, fly ash, crystallization and bonding conditions, and is not affected by temperature. After installing the adapter, it can work at 1600℃ at most, and the pressure is not affected at 60MPa. Due to the working mode of frequency modulation continuous wave, the material level reaction speed is extremely fast. The accuracy can reach 1mm, and the range can reach 150m. These characteristics are not achieved by most brands of radar level detection technology

4. In the current market, the price is also the key consideration of the user. In order to improve the overall competitiveness of Jinde company, the company can also provide 26GHz pulse radar produced by joint venture with foreign countries. For some simple solid working conditions, most liquids and silos with measuring range less than 70m, we can provide this product with competitive price. We also produce ultrasonic liquid level meter, magnetic flap liquid level meter, floating ball liquid level meter, various liquid level switches and material level switches to meet the various needs of customers.

In the future, we will gradually analyze and solve the difficulties of level detection in various typical industries

上一篇:BEIJING JINDE CHUANGYE WAS INVITED TO ATTEND THE 13TH CEMENT TECHNOLOGY EXCHANGE SUMMIT IN 2020 下一篇:The added value of China's instrument industry is growing continuously